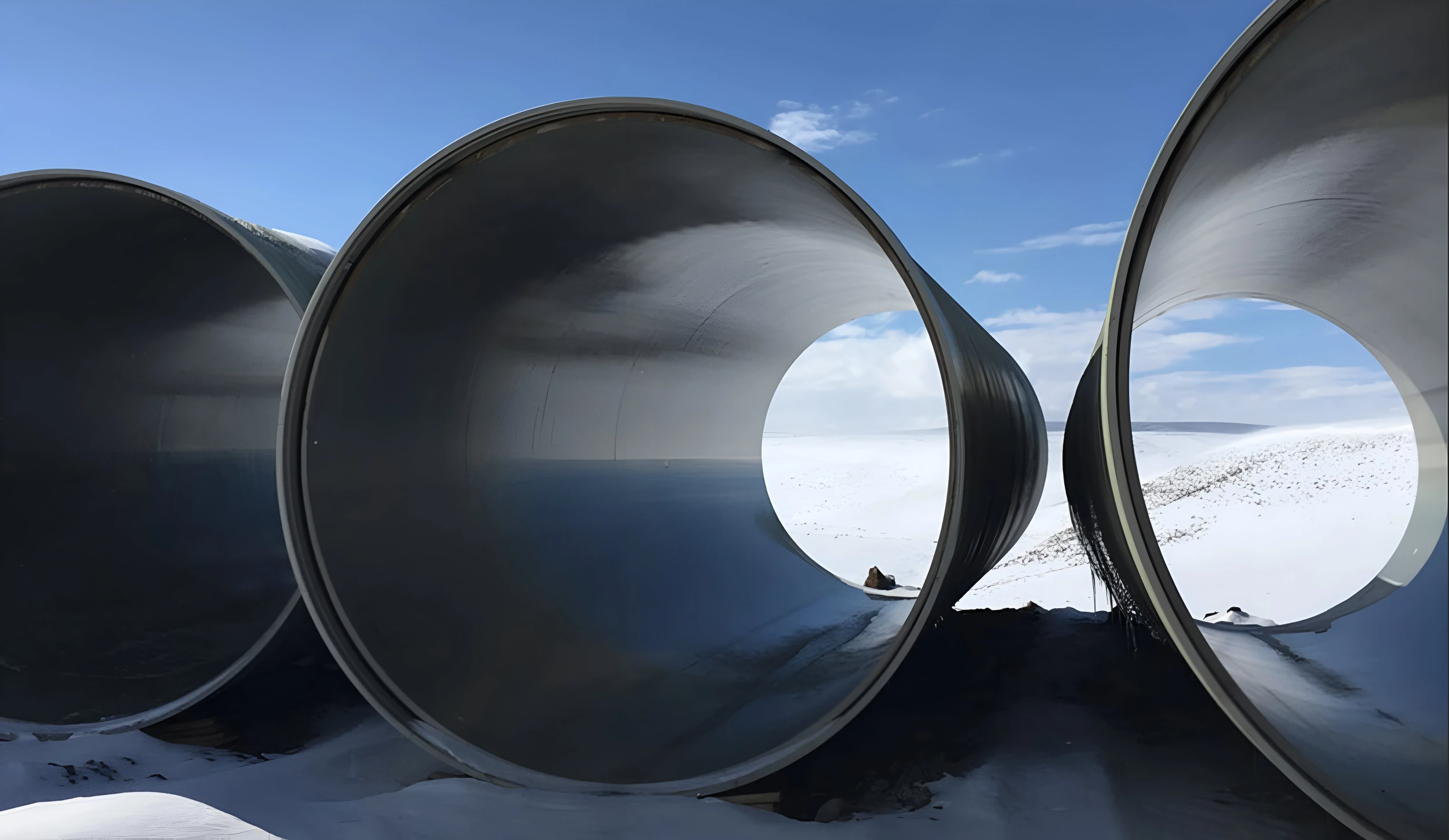

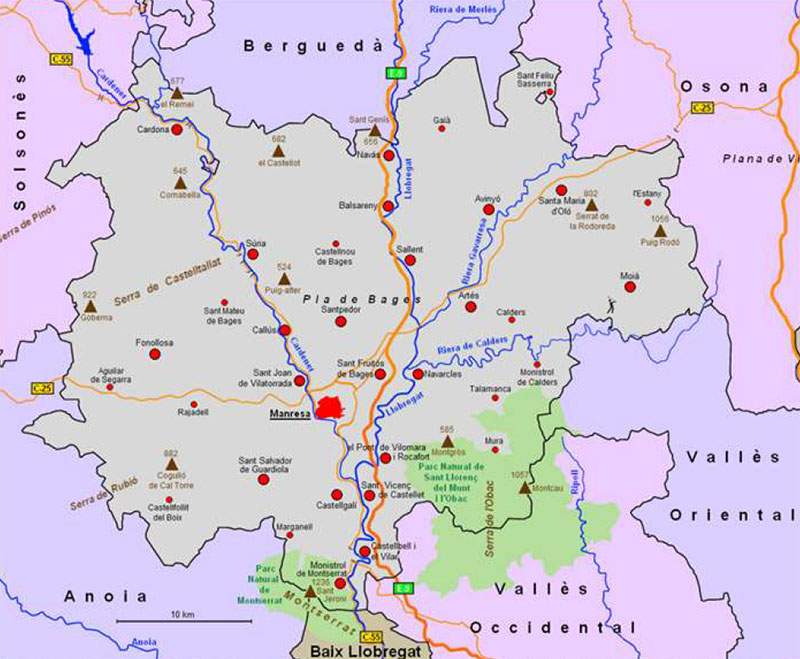

(Pla Palous – Castellgalí, Barcelona)

PROJECT DETAILS

| Country | Spain |

|---|---|

| City | Barcelona |

| Type of Project | Environmental Infrastructure Brine Collection |

| Type of Pipe | Pressure GRP Pipes |

| Total Length of Pipe | 12 KM |

| Nom. Diameter DN (mm) | DN600 |

| Nom. Pressure PN (bar) | 10 |

| Nom. Stiffness SN (N/mm²) | SN5000 |

| Joint Types | Double Bell Reka Coupling |

| Standard / Design | UNE-EN ISO 23856:2023 & CEDEX Guide |

| Client | ACA - Agència Catalana de l’Aigua |

| Main Contractor | Sorigué – Copisa – Acsa JV |

| Project Duration | 2025 - 2026 |

Its objective is to collect and transport high-salinity brine (“Salmorres”) from mining and industrial areas to treatment and disposal points, preventing contamination of the Llobregat and Cardener river basins.

For Lote 2, Subor supplied 12 km of DN 600 GRP pipes, designed and manufactured fully in accordance with the CEDEX Technical Guide and UNE-EN ISO 23856 standard — the latest European framework for buried GRP pipeline systems.

The project showcases Subor’s engineering expertise, international standard compliance, and long-term partnership approach with Spain’s public-works institutions.

Technical Aspects of the Project

- Design in compliance with UNE-EN ISO 23856 ensuring performance for ? 50 years service life.

- CEDEX Guide parameters applied for hydraulic, structural, and chemical design.

- Polyester resin system with ECR-Glass veil for high chloride & sulfate resistance.

- Internal roughness k = 0.029 mm › optimized head loss and energy efficiency.

- REKA coupling with EPDM gaskets › flexible, leak-proof jointing.

Manufacturing & Quality Control

- Manufactured at SUBOR Sakarya Plant (Türkiye) under ISO 9001 / 14001 / 45001 certification.

- Tests conducted per CEDEX & UNE-EN ISO 23856:

- Hydrostatic pressure (1.5 × PN)

- Long-term ring stiffness (? 10 000 h)

- Axial tensile & interlaminar shear

- Liner thickness & barcol hardness

- Dimensional tolerances & ovalization checks

PROJECT DETAILS

| Country | Ivory Coast |

|---|---|

| City | Abengourou |

| Application | Water Supply |

| Installation | Buried |

| Type of Pipe | Uniaxial |

| Total Length of Pipe | 20km |

| Nom. Diameter DN (mm) | DN300–DN500 |

| Nom. Pressure PN (bar) | 20 |

| Nom. Stiffness SN (N/mm²) | SN10000 |

| Joint Types | REKA Coupling |

| Fittings | 262Pcs |

| Project Duration | 3 years |

| Year Start / Year End | 2019/ 2021 |

SUBOR supplied 20 kilometers of high-pressure GRP pipelines ranging from DN300 to DN500, all rated at PN20 and SN10000, alongside 262 custom-designed fittings. All materials were engineered to meet the region’s technical and hydraulic demands, including elevated pressure conditions, high safety standards, and longevity expectations in challenging soil environments. The pipe design and buried installation engineering were fully developed by SUBOR’s technical department, ensuring seamless project execution.

The new transmission line connects to several critical distribution networks and has already provided safe drinking water to nearly 280,000 residents. By 2025, the system is expected to serve over 350,000 people, making it one of the most impactful regional water infrastructure investments in recent years. The water delivered is not only potable but also of excellent organoleptic quality—a testament to the commitment to health, taste, and quality.

This project is more than infrastructure—it’s a promise delivered. By bringing reliable access to clean water, it significantly improves public health, reduces dependency on unsafe water sources, and contributes to economic stability in Abengourou and surrounding areas. Clean water access underpins education, agriculture, and daily life—and SUBOR is proud to support such a vital foundation for community growth.

PROJECT DETAILS

| Country | Kenya |

|---|---|

| City | Bomet |

| Application | Water Supply |

| Installation | Buried |

| Type of Pipe | Uniaxial |

| Total Length of Pipe | 17 km |

| Nom. Diameter DN (mm) | DN400 –DN700 |

| Nom. Pressure PN (bar) | 16 |

| Nom. Stiffness SN (N/mm²) | SN5000 |

| Joint Types | REKA Coupling |

| Fittings | 300 Pcs |

| Year Start | 2023 |

As a trusted provider of advanced GRP piping systems, SUBOR was selected by contractor China Railway No. 10 Engineering Group Ltd. to supply a tailored pipeline solution that meets the high-performance needs of this ambitious project. SUBOR’s supply package included:

- 17 kmofDN400–700 mmPN16SN5000 GRPpipes

- 300 precision-engineered fittings

- Technical consultation and design collaboration to ensure reliable buried pipeline performance

PROJECT DETAILS

| Country | Ethiopia |

|---|---|

| City | Chelchel Region |

| Application | Water Supply |

| Installation | Buried |

| Type of Pipe | Uniaxial |

| Total Length of Pipe | 600 m |

| Nom. Diameter DN (mm) | DN200-DN1100 |

| Nom. Pressure PN (bar) | 10 |

| Nom. Stiffness SN (N/mm²) | SN5000 |

| Joint Types | REKA Coupling |

| Fittings | 75 Pcs |

| Project Duration | 3 years |

| Year Start | 2024 |

As part of this development, SUBOR supplied 600 meters of DN1100, PN10, SN5000 GRP pipes and 75 custom-engineered fittings. All engineering drawings, hydraulic designs, and buried pipe system calculations were provided directly by SUBOR’s in-house technical team, ensuring seamless integration into the project's infrastructure. The project’s topographical complexity and the demanding environmental conditions made it essential to deliver a high-performance, corrosion resistant solution—which is where SUBOR’s GRP technology excelled.

This marks SUBOR’s first-ever project in Ethiopia, solidifying the company’s footprint in East Africa. It also exemplifies SUBOR’s capability to deliver technically advanced solutions for large-scale, high-impact public infrastructure works across challenging geographies. The reliability and durability of our pipe systems played a critical role in addressing the demanding operational and environmental conditions of the region.

SUBOR’s involvement in the Chelchel Irrigation Project represents more than just product delivery; it demonstrates a commitment to sustainable water infrastructure, agricultural empowerment, and regional development. As we continue to expand our presence in Africa, projects like Chelchel reinforce SUBOR’s role as a trusted global partner in water management and infrastructure innovation.

PROJECT DETAILS

| Year | 2015 |

|---|---|

| Operating pressure | 8bar |

| Installation Method(s) | Underground & Aboveground |

| Pipe Diameter(s) | 400-1500mm |

| Pressure /Stiffness Class | 10 bars - 10000 N/m2 |

| Coupling Type | Subor REKA Type Pressure Coupling |

| Project Length | 850m |

| Pipe Standard | ISO 23856 |

| Project Purpose | Geothermal Project |

| Owner | Güriş Makina ve Montaj Sanayi A.Ş. |

| Project Location | Aydin, Germencik, Turkiye |

In the scope of this project, Subor GRP Pipes were used for the cooling water tower connection for the plant. GRP pipes were installed in both aboveground and underground. Also, Subor technicians supervised the project for the lamination of the spools, inside of the plant.

Engineered to last, Subor to provided a solution for pipe systems for the pressure design of 10 bars with a cost advantage against conventional materials. Operational temperature of the pipeline was too high so that special vinyl-ester type of pipes were used for this project for the protection of up to 80C°. With the benefit of SUBOR GRP Pipes’ structure, lower wave celerity than other piping materials can mean less cost when designing for surge and water hammer pressures.

Subor coordinated with Güriş Makina ve Montaj Sanayi A.Ş. to successfully complete this project which is commissioned in March 2015 to bring electricity to local communities. Subor staff were present at the jobsite in each stage of the project’s installation.

Figure 1. Subor GRP Pipes were installed inside of the plant for the cooling water system.

Figure 2. Unit 1 of the Efeler Plant were commissioned in 2015. After the commissioning of the next units, Efeler will be the largest geothermal plant of Turkiye.

PROJECT DETAILS

| Year | 2017-ongoing |

|---|---|

| Operating pressure | 10 bars |

| Installation Method(s) | Open Trench |

| Pipe Diameter(s) | 600-3400mm |

| Pressure /Stiffness Class | 6-16 bar – 5000 N/m2 |

| Coupling Type | Subor REKA Type Pressure Coupling |

| Project Length | 58,000m |

| Pipe Standard | ISO 23856 |

| Project Purpose | Irrigation |

| Owner | Turkish State Hydraulic Works (DSI) |

| Project Location | Bünyan, Kayseri Turkey |

With the completion of the project, product diversity in the region will increase and agriculture-based industry will develop, contributing to the socio-economic development of the people of the region.

Engineered to last, SUBOR to provided a solution for pressure pipe systems for the pressure design of 6-16 bars with a cost advantage against conventional materials. With the benefit of SUBOR GRP Pipes’ structure, lower wave celerity than other piping materials can mean less cost when designing for surge and water hammer pressures.

Subor coordinated with the General Directorate of State Hydraulic Works (DSI) to popularize modern irrigation in agriculture, to get the most benefit from agricultural lands, to deliver healthy and drinkable water to taps, and to protect settlements and agricultural lands against flood risks, sustainable water supply It protects every drop of water with its management approach.

Figure 1. Subor Technicians are conducting final quality checks for the GRP pipe that is about to be installed.

Figure 2. GRP to Steel connection with Subor GRP Flanges for the water flow control chamber.

PROJECT DETAILS

| Country | Ivory Coast |

|---|---|

| City | Abidjan |

| Application | Water Treatment Plant |

| Installation | Hybrid |

| Type of Pipe | Uniaxial & Biaxial |

| Total Length of Pipe | 15 km |

| Nom. Diameter DN (mm) | DN200 - DN1200 |

| Nom. Pressure PN (bar) | 6-25 |

| Nom. Stiffness SN (N/mm²) | SN10000 |

| Joint Types | REKA & Butt-Wrap |

| Fittings | 400 Pcs |

| Project Duration | 4 years |

| Year Start / Year End | 2021 / 2025 |

SUBOR played acritical engineering and supply role in this flagship project, working closely with Fluence Corporation (Client) and LAVISO (Contractor) to provide custom pipe solutions and on-site technical support from project inception through to near-completion.

- Full engineering support, including pipe system design, mechanical drawings, and buried pipe calculations.

- Supply of both biaxial and uniaxial GRP pipe systems, with biaxial pipes used in loose soil conditions to ensure long-term stability and resistance to deformation.

- Custom-fabricated spools and fittings, precisely designed to meet the complex layout of the water treatment facility.

- Long-term site presence: SUBOR supervisors remained on-site for over a year, ensuring seamless integration, proper installation practices, and close coordination with project stakeholders.

PROJECT DETAILS

| Year | 2016 |

|---|---|

| Operating pressure | Gravity |

| Installation Method(s) | Open Trench |

| Pipe Diameter(s) | 400-2400mm |

| Pressure /Stiffness Class | 6-10 bars - 5000 N/m2 |

| Coupling Type | Subor REKA Type Pressure Coupling |

| Project Length | 190,000 |

| Pipe Standard | ISO 23856 |

| Project Purpose | Irrigation |

| Owner | Turkish State Hydraulic Works (DSI) |

| Project Location | Mardin, Turkey |

Subor continues to bring water to fertile lands, provide drinking and utility water to the citizens, and reduce the risk of floods in streams with its investments. recent increase in water structures built in the districts of Mardin provinces plays an important role in the development of agricultural activiti1es in the region.

In this context, within the scope of the Mardin Ceylanpinar Plains Gravity Irrigation Project, works were completed in an area of 23 thousand hectares. With the completion of the entire project, irrigation with groundwater will come to a halt. A great progress will be made in solving the drought problem, which has been the biggest problem of the Mardin region for years.

Engineered to last, SUBOR to provided a solution for pipe systems for the pressure design of 6-10 bars with a cost advantage against conventional materials. With the benefit of SUBOR GRP Pipes’ structure, lower wave celerity than other piping materials can mean less cost when designing for surge and water hammer pressures.

Subor coordinated with the General Directorate of State Hydraulic Works (DSI) to popularize modern irrigation in agriculture, to get the most benefit from agricultural lands, to deliver healthy and drinkable water to taps, and to protect settlements and agricultural lands against flood risks, sustainable water supply It protects every drop of water with its management approach.

Figure 1. Subor Technician is controlling the altitude of the GRP Pipeline according to project requirements.

Figure 2. Subor GRP Pipes are used to irrigate the barren lands of Mardin.

PROJECT DETAILS

| Year | 2018 |

|---|---|

| Operating pressure | 16 |

| Installation Method(s) | Aboveground |

| Pipe Diameter(s) | 2200mm |

| Pressure /Stiffness Class | 20 bars - 5000 N/m2 |

| Coupling Type | Subor REKA Type Pressure Coupling |

| Project Length | 850m |

| Pipe Standard | ISO 23856 |

| Project Purpose | Hydropower |

| Owner | PA Technical Services |

| Project Location | Nkusi Falls, Hoima District |

Subor offered pressure pipes in it’s Glass fiber Reinforced Pipe (GRP) for a project of the power station is a run-of-river hydro power plant with installed capacity of 9.6 megawatts (12,900 hp).

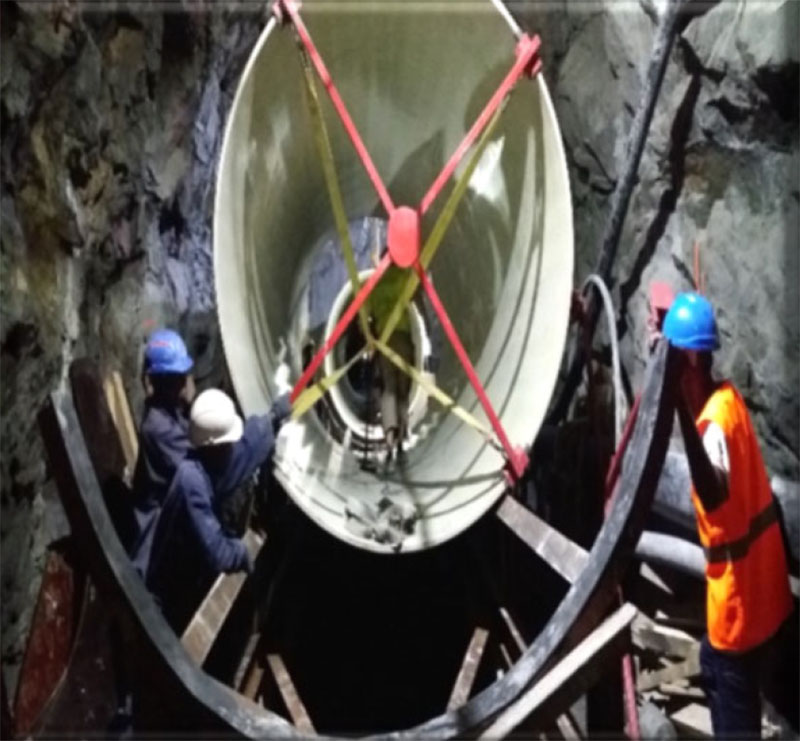

In the scope of this project, Subor GRP Pipes were used for the penstock of the Hydropower Project. GRP pipes were installed in tough conditions such as drilling the mountain to construct a tunnel structure and installing GRP pipes inside of this tunnel.

Engineered to last, Subor to provided a solution for pipe systems for the pressure design of 16 bars with a cost advantage against conventional materials. With the benefit of SUBOR GRP Pipes’ structure, lower wave celerity than other piping materials can mean less cost when designing for surge and water hammer pressures.

Subor coordinated with the Norwegian Contractor PA Technical Services to successfully complete this project which is commissioned in March 2018 to bring electricity to Ugandan communities. Subor staff were present at the jobsite in each stage of the project’s installation.

Figure 1. Subor GRP Pipes were installed with the

help of steel supports to move the pipes inside of the

tunnel.

Figure 2. Subor GRP Pipes are stocked in the jobsite

ready to be installed.

PROJECT DETAILS

| Country | Kenya |

|---|---|

| City | Nairobi |

| Application | Water Supply |

| Installation | Buried |

| Type of Pipe | Uniaxial |

| Total Length of Pipe | 12 km |

| Nom. Diameter DN (mm) | DN800-DN1000 |

| Nom. Pressure PN (bar) | 10 |

| Nom. Stiffness SN (N/mm²) | SN5000 |

| Joint Types | REKA Coupling |

| Fittings | 270 Pcs |

| Project Duration | 2 years |

| Year Start / Year End | 2021 / 2023 |

SUBOR supplied 11 kilometers of GRP pipes an3d 270 fittings, designed and engineered to meet the unique hydraulic and geological requirements of the region. All engineering drawings and buried pipe system design were prepared by SUBOR’s experienced technical team, ensuring precision and system integrity throughout the project’s demanding conditions.

This project is set to supply an additional 13 million liters of water per day to residents of Ruiru, Juja, and Githurai, reaching more than 400,000 people across Nairobi and parts of Central Kenya. The water distribution network, overseen by Ruiru-Juja Water and Sewerage Company, SUBOR’s GRP solutions were selected for key pipeline segments due to their long-term durability, corrosion resistance, and ease of installation — all critical for high-demand urban networks.

The Ruiru-Juja-Githurai initiative is part of a larger water security strategy led by Kenya’s Ministry of Water and Sanitation. Nairobi has long suffered from severe water rationing, with many households receiving water only once or twice a week and relying on high-cost vendors. The expansion of infrastructure is expected to dramatically improve access and affordability.

SUBOR’s involvement in this high-impact project demonstrates our growing footprint in East Africa and our commitment to sustainable water management. Working alongside local partners and public institutions, SUBOR continues to deliver world-class GRP piping systems that drive real change in water-stressed regions. We are honored to play a part in Kenya’s water resilience journey.

PROJECT DETAILS

| Year | 2023 |

|---|---|

| Operating pressure | Gravity |

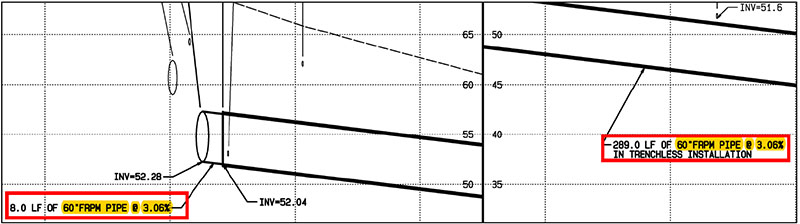

| Installation Method(s) | Microtunneling– Trenchless & Open Cut |

| Pipe Diameter(s) | 66in. & 60in. |

| Pressure /Stiffness Class | 50psi / 270psi for DN60 MT, 50psi / 290psi for DN66 MT, 50psi / 46psi for DN60 Open Cut, 50psi / 46psi for DN66 Open Cut |

| Coupling Type | Flush for MT & Reka for Open Cut |

| Project Length | 3,100 ft |

| Pipe Standard | ASTM D3262 |

| Project Purpose | New Installation |

| Contractor | Minger Construction Inc. |

| Owner | City of Des Moines |

| Project Location | Des Moines, IA |

Engineered to last, HAR liner was chosen specifically because of the expected abrasive conditions of the flow. Steep slopes in a gravity flow application cause high velocities in sewage which can erode the interior of a non-lined pipe (See Figure 1). Manufactured into the wall of the FRP, which is a chemically corrosion resistant pipe, the HAR liner ensures that the pipe can handle the high velocities that can be expected at higher flows (See Figure 2).

The MT trenchless method was ideal to avoid road closures, public disruption, and existing water and sewer utilities in the heart of the metropolitan city (See Figure 3).

Figure 1. In this case a 3.06% slope for the 60" line was resulting in flow velocities exceeding the recommended 16ft/s. High velocity flows can cause erosion of the interior of the pipe over time if not lined.

Figure 2. Embedded into the interior wall of the pipe during production on the winder, the HAR liner adheres to the pipe as part of a monolithic unit, preventing peeling in the typical manner as aftermarket liner applications. Tested for abrasion according to Darmstadt methods, the liner performs 10x better than the standard liner. The HAR liner product by Subor is fit for abrasive flow conditions, caused either by high velocities or solids in the conveyed fluid.

Figure 3. Our Subor GRP MT pipe is designed to handle jacking loads, dead, and live loads as seen with traffic crossing overhead the tunnel.

PROJECT DETAILS

| Year | 2017 |

|---|---|

| Operating pressure | 3bar |

| Installation Method(s) | Underground & Aboveground |

| Pipe Diameter(s) | 200-1400mm |

| Pressure /Stiffness Class | 6 bars - 10000 N/m2 |

| Coupling Type | Subor Lamination Joint |

| Project Length | 1300m |

| Pipe Standard | ISO 23856 |

| Project Purpose | Geothermal Project |

| Owner | Zorlu Enerji |

| Project Location | Denizli, Buharkent, Turkiye |

In the scope of this project, Subor GRP Biaxial Pipes were used for the cooling water tower connection and inlet/outlet system of the plant. GRP pipes were installed in both aboveground and underground. Also, Subor technicians supervised the lamination connections of the Biaxial pipes. Special 1m long REKA Type Couplings were used for this project.

Engineered to last, Subor to provided a solution for pipe systems for the pressure design of 6 bars with a cost advantage against conventional materials. Operational temperature of the pipeline was too high so that special vinyl-ester type of pipes were used for this project for the protection of up to 80C°. With the benefit of SUBOR GRP Pipes’ structure, lower wave celerity than other piping materials can mean less cost when designing for surge and water hammer pressures.

Subor coordinated with Zorlu Enerji with each step of this project to successfully complete this project which is commissioned in June 2017 to bring electricity and energy to local communities. During the wintertime, more than 4000 houses are heated thanks to Kizildere. Subor staff were present at the jobsite in each stage of the project’s installation.

Figure 1. Subor GRP Pipes were installed inside of the plant for the cooling water connection.

Figure 2. Kizildere plant is operation since 2017 bringing clean energy to many communities.

PROJECT DETAILS

| Country | Egypt |

|---|---|

| City | Cairo |

| Application | Irrigation |

| Installation | Buried |

| Type of Pipe | Uniaxial |

| Total Length of Pipe | - |

| Nom. Diameter DN (mm) | DN1200 –DN2800 |

| Nom. Pressure PN (bar) | 16 |

| Nom. Stiffness SN (N/mm²) | SN5000 |

| Joint Types | REKA Coupling |

| Fittings | 52 Pcs |

| Project Duration | 2 months |

| Year | 2025 |

To support the complex hydraulic requirements of this mega-project, Subor supplied 52 units of special largediameter GRP fittings, demonstrating exceptional manufacturing versatility. The scope included a variety of critical components such as Tee Pieces, Reducers, Flanges, and Elbows, with massive diameters ranging from DN1200 up to DN2800. Designed to withstand high-pressure environments, these fittings were manufactured to a PN16 pressure rating, ensuring durability and reliability in the demanding irrigation network. This delivery serves as a testament to Subor advanced production capacity, specifically regarding large-scale, complex fitting fabrication.

Beyond manufacturing, Subor acted as a comprehensive solution partner through its engineering capabilities. The Subor Engineering Team provided detailed design support and technical drawings for these fittings for seamless integration into the wider network. By delivering these specialized engineering solutions, Subor has successfully contributed to the backbone of Egypt’s agricultural expansion, supporting a project that will drive economic growth and food sustainability for generations to come.