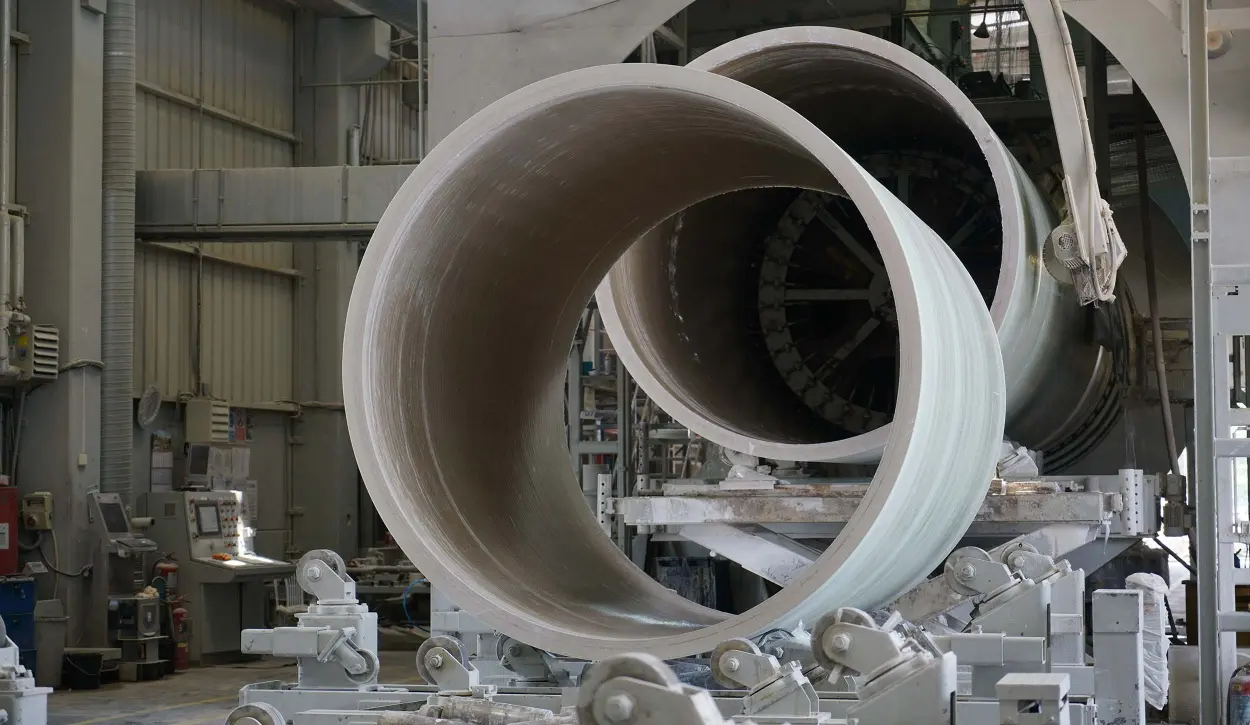

The most advanced GRP pipe manufacturing process.

Continuous Filament Winding (CFW) Technology is a fully computer-controlled production system that ensures precision, strength and consistency in every meter of pipe.

During production, glass fibers are wound around a continuously rotating mandrel to form the pipe’s internal and external structural layers. These layers deliver exceptional pressure resistance and rigidity, while chopped glass fibers provide superior axial strength across all layers. Depending on project requirements, the glass reinforcement arrangement can be configured as uniaxial or biaxial, optimizing performance for specific design conditions.

A high-quality polyester resin system binds the fibers through a thermoset polymerization reaction, creating a durable composite. For special operating environments, the resin formulation can be tailored to provide enhanced chemical resistance, heat resistance, flame retardancy, or meet any other project-specific requirements.

At the pipe’s core, silica sand acts as a reinforcing filler, increasing stiffness and mechanical performance in a cost-efficient way.

The result is a product that combines advanced engineering and optimized materials, setting the standard for GRP pipe manufacturing worldwide.

During production, glass fibers are wound around a continuously rotating mandrel to form the pipe’s internal and external structural layers. These layers deliver exceptional pressure resistance and rigidity, while chopped glass fibers provide superior axial strength across all layers. Depending on project requirements, the glass reinforcement arrangement can be configured as uniaxial or biaxial, optimizing performance for specific design conditions.

A high-quality polyester resin system binds the fibers through a thermoset polymerization reaction, creating a durable composite. For special operating environments, the resin formulation can be tailored to provide enhanced chemical resistance, heat resistance, flame retardancy, or meet any other project-specific requirements.

At the pipe’s core, silica sand acts as a reinforcing filler, increasing stiffness and mechanical performance in a cost-efficient way.

The result is a product that combines advanced engineering and optimized materials, setting the standard for GRP pipe manufacturing worldwide.

Advantages of GRP Pipes

Corrosion / Abrasion Resistance

Unlike traditional materials such as steel or ductile iron, GRP pipes do not rust, corrode, or degrade when exposed to aggressive environments. This makes them ideal for a wide range of fluid applications, including corrosive chemicals, seawater, industrial effluents and saline groundwater.

The composite structure provides long-term protection against chemical exposure and surface wear, even under continuous flow and abrasive conditions. As a result, no additional internal linings or external coatings are required, significantly reducing maintenance needs and lifecycle costs, while ensuring long-term reliability and performance.

The composite structure provides long-term protection against chemical exposure and surface wear, even under continuous flow and abrasive conditions. As a result, no additional internal linings or external coatings are required, significantly reducing maintenance needs and lifecycle costs, while ensuring long-term reliability and performance.

Lightweight

GRP pipes are remarkably lightweight, weighing approximately one-tenth of concrete and one-fourth of steel pipes.

This low weight eliminates the need for heavy lifting or specialized handling equipment, allowing for faster, safer and more cost-efficient installation on site.

For optimized transportation, pipes of various diameters can be nested so that the smaller pipes are inserted inside larger ones and shipped as a compact set using specially designed packaging. This method maintains the hydraulic properties and inner surface smoothness of each pipe while minimizing space requirements.

This efficient logistics method provides significant savings in transportation and handling costs, making GRP pipes a smart and sustainable choice for modern infrastructure projects.

This low weight eliminates the need for heavy lifting or specialized handling equipment, allowing for faster, safer and more cost-efficient installation on site.

For optimized transportation, pipes of various diameters can be nested so that the smaller pipes are inserted inside larger ones and shipped as a compact set using specially designed packaging. This method maintains the hydraulic properties and inner surface smoothness of each pipe while minimizing space requirements.

This efficient logistics method provides significant savings in transportation and handling costs, making GRP pipes a smart and sustainable choice for modern infrastructure projects.

Superior Hydraulic Properties

The superior hydraulic performance of GRP pipes ensures consistent flow capacity and operational stability throughout their entire service life.

Thanks to their exceptionally smooth internal surface, GRP pipes prevent the buildup of lime, scale, and sediment deposits, maintaining their original hydraulic efficiency over decades of operation.

Unlike conventional materials, the long-lasting smoothness and optimized structural design of GRP allow larger inner diameters to be achieved at the same pressure class. This provides higher flow capacity and enables smaller nominal diameters to deliver the same flow rate, optimizing both system design and cost efficiency.

Minimal friction losses ensure lower energy consumption for pumping systems and increased energy generation efficiency in hydropower applications, delivering both operational savings and sustainable.

Thanks to their exceptionally smooth internal surface, GRP pipes prevent the buildup of lime, scale, and sediment deposits, maintaining their original hydraulic efficiency over decades of operation.

Unlike conventional materials, the long-lasting smoothness and optimized structural design of GRP allow larger inner diameters to be achieved at the same pressure class. This provides higher flow capacity and enables smaller nominal diameters to deliver the same flow rate, optimizing both system design and cost efficiency.

Minimal friction losses ensure lower energy consumption for pumping systems and increased energy generation efficiency in hydropower applications, delivering both operational savings and sustainable.

Long Service Life

Subor GRP Pipes are designed and verified through extensive Long-Term Tests conducted in Subor’s accredited laboratories, in full compliance with international standards.

These tests confirm that Subor pipes maintain their original mechanical and hydraulic performance even after 50 years of continuous service, representing a substantial improvement compared to metallic or concrete pipes, which typically require regular maintenance or replacement within that period.

The design code for Subor glass-reinforced pressure pipes is the AWWA C950 Fiberglass Pipe Standard, which specifies a standard design safety factor applied to a 50-year design life for water supply systems. Furthermore, Hydrostatic Design Basis (HDB) data can be extrapolated beyond 50 years, reflecting the time-dependent behavior of GRP materials. This allows Subor GRP pipes to be designed for extended lifespans — up to 150 years — within defined strain limits, offering exceptional long-term reliability and sustainability.

These tests confirm that Subor pipes maintain their original mechanical and hydraulic performance even after 50 years of continuous service, representing a substantial improvement compared to metallic or concrete pipes, which typically require regular maintenance or replacement within that period.

The design code for Subor glass-reinforced pressure pipes is the AWWA C950 Fiberglass Pipe Standard, which specifies a standard design safety factor applied to a 50-year design life for water supply systems. Furthermore, Hydrostatic Design Basis (HDB) data can be extrapolated beyond 50 years, reflecting the time-dependent behavior of GRP materials. This allows Subor GRP pipes to be designed for extended lifespans — up to 150 years — within defined strain limits, offering exceptional long-term reliability and sustainability.

Fast and Easy Installation

GRP pipes are engineered for quick, safe, and efficient installation. Using GRP couplings, there is no need for highly specialized workers or welding equipment, simplifying site operations and reducing labor costs.

A skilled installation team can typically install around 300 meters of DN1200 mm pipe in a single day, demonstrating the speed and efficiency of GRP systems compared to traditional materials.

The lightweight construction of GRP pipes eliminates the need for heavy lifting machinery and reduces handling risks, while flexible jointing allows minor on-site adjustments to accommodate alignment and terrain variations.

All these features make Subor GRP pipes a practical, cost-effective and reliable solution for modern infrastructure projects.

A skilled installation team can typically install around 300 meters of DN1200 mm pipe in a single day, demonstrating the speed and efficiency of GRP systems compared to traditional materials.

The lightweight construction of GRP pipes eliminates the need for heavy lifting machinery and reduces handling risks, while flexible jointing allows minor on-site adjustments to accommodate alignment and terrain variations.

All these features make Subor GRP pipes a practical, cost-effective and reliable solution for modern infrastructure projects.

UV Resistance

GRP pipes provide exceptional UV and temperature resistance, making them ideal for hot climates. Their mechanical properties remain stable across a wide temperature range, from -30°C to +50°C, ensuring reliable performance in both extreme cold and intense heat. This durability allows above-ground installation without the need for special UV protection, reducing installation costs and maintenance while sustaining long-term performance.

Subor Non-Circular (NC) GRP Pipe Technology

Subor NC GRP Pipe Technology involves using a discontinuous filament winding process, where glass fibers are wound around a rotating mold to form the pipe structure. Both woven and chopped glass fibers are incorporated to provide axial and radial resistance and the fibers are bound by high-quality polyester resin to create a durable composite.

This technology allows the production of custom-shaped pipes to meet any project requirement, including egg-shaped, horseshoe, arch, mouth-shaped or other specialized profiles. Regardless of shape, the jointing system is standardized with bell and spigot connections, ensuring reliable and leak-free installation.

With Subor NC GRP Technology, projects gain the strength, flexibility and customization needed for complex hydraulic and structural applications.

This technology allows the production of custom-shaped pipes to meet any project requirement, including egg-shaped, horseshoe, arch, mouth-shaped or other specialized profiles. Regardless of shape, the jointing system is standardized with bell and spigot connections, ensuring reliable and leak-free installation.

With Subor NC GRP Technology, projects gain the strength, flexibility and customization needed for complex hydraulic and structural applications.