Buried Installation

When properly designed and executed, Subor GRP pipelines deliver outstanding reliability and durability in buried applications.

Need help with static calculations? Fill out the form — our engineers will be happy to assist you.

The bedding is the backfill material placed at the bottom of the trench or on top of the foundation when required. Its primary function is to provide a stable, uniform surface for laying the pipe, ensuring proper alignment and support along the entire pipeline.

Backfill refers to the material placed around the sides of the pipe and extending up to 300 mm above the pipe. These materials are categorized into different groups according to their stiffness when compacted, as outlined in the classification table.

Where compaction is required, proper equipment such as surface vibrators should be used to achieve the specified density and secure long-term pipeline stability.

Final backfill refers to the material placed from the top of the initial backfill layer up to the ground surface, serving to protect the pipe and maintain the integrity of the pipe embedment. Depending on the backfill material, a minimum cover of 0.8 m to 1.2 m is required; however, in areas where buoyancy may compromise stability, the burial depth must be at least equal to the pipe diameter to prevent uplift.

When a pipeline is subjected to internal pressure, unbalanced hydrostatic thrust forces occur at points where the direction changes. If not controlled, these forces can cause joint separation and structural damage due to pipeline movement. To further enhance performance, rocker pipes must be placed before and after the thrust block to eliminate shear forces and accommodate allowable deflection.

A thrust block is used to restrain these forces, providing stability and protecting the integrity of the pipeline system.

When connecting GRP pipes to rigid structures, short pipes known as rocker pipes should be used. These minimize bending and shear stresses that may occur due to differential settlement between the pipeline system and the rigid structure.

Rocker pipes must be installed in straight alignment, and the surrounding soil should be carefully and properly compacted to ensure long-term stability and protection of the connection. Subor offers wall couplings, where the exterior surface is augmented with gravel to achieve stronger cohesion with the existing structure and concrete.

Aboveground Installation

Depending on the specific requirements of your project, different design provisions and support methods may be necessary to achieve optimal performance. Subor provides guidance on appropriate design parameters and installation practices, helping you achieve a safe, efficient and durable piping system.

Trenchless Solutions

To ensure a perfect fit, we provide custom-engineered pipes with tailor-made characteristics optimized for your specific project needs.

Subor GRP pipes provide a superior solution for the renovation of existing pipelines through sliplining. Designed with sleeve couplings, our system allows the pipes to slide smoothly into the existing pipeline, ensuring fast and efficient installation without reducing flow capacity. Combined with the inherent advantages of GRP—superior hydraulic performance, exceptional chemical resistance, and long service life—Subor offers a reliable and cost-effective alternative to traditional pipeline replacement.

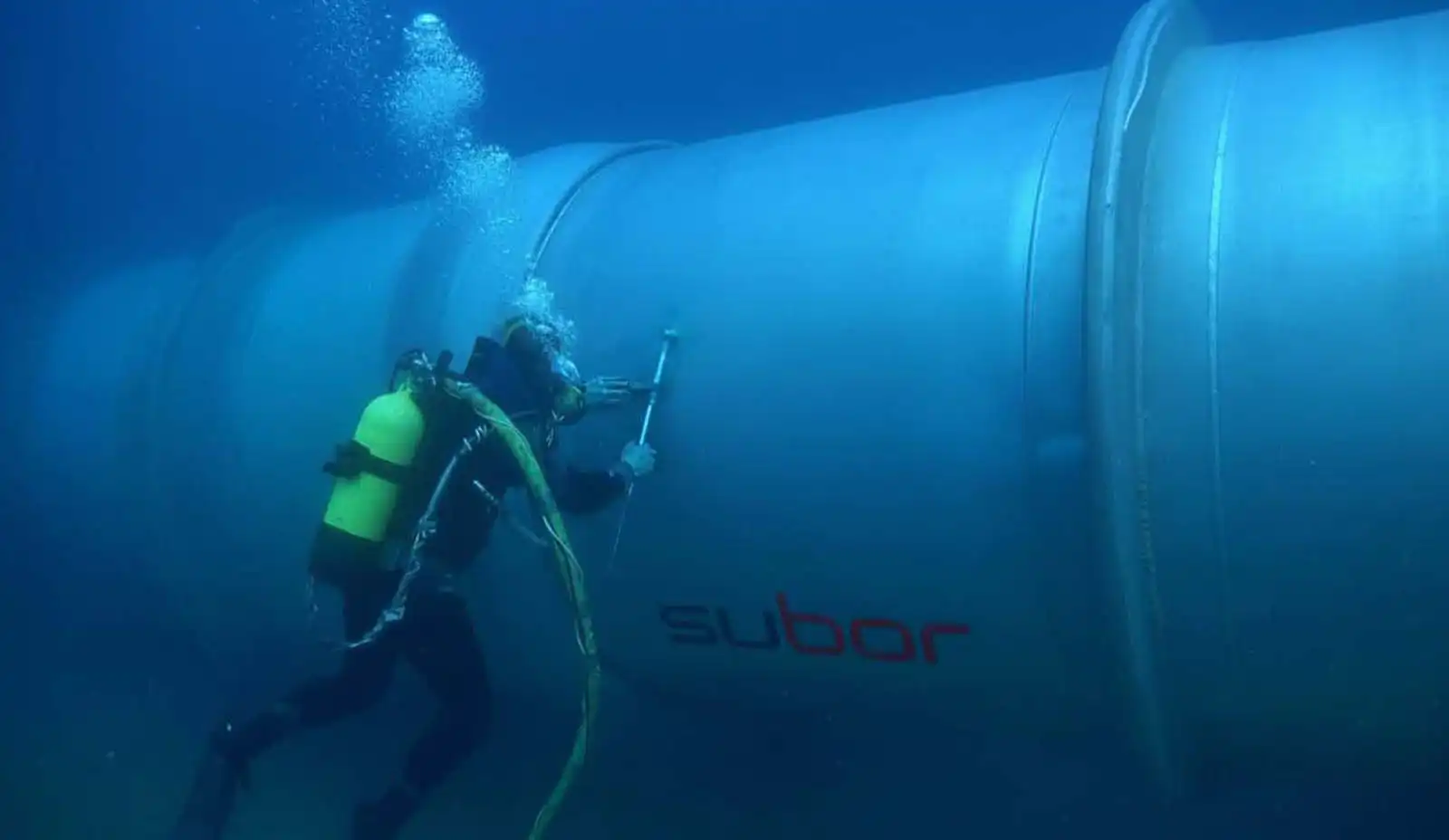

Subaqueous Installation

For underwater installation, marine harness lugs are applied on the pipe surface near the couplings. These lugs are designed to serve multiple purposes during underwater installation. They keep the pipe strings properly aligned and provides reliable support for safe and efficient jointing below the water surface, while also assisting divers during loading, transfer and sinking operations.